ISO Certified

A.R.E. Manufacturing, Inc. understands that quality assurance is a continuous process of improvement. From first article to final inspection, our entire staff monitors quality throughout the manufacturing process. With the use of a Coordinate Measuring Machine (CMM), regularly calibrated equipment, standardized documentation and an experienced, certified staff, we ensure precision and quality in all our products.

Additionally, we see quality as more than just making parts to print. Quality at A.R.E. Manufacturing, Inc. involves meeting customer needs in an efficient and effective manner.This is evident in our prompt response to customer concerns, precise attention to detail, and continuous improvement of our processes. Combining multi-level inspection, continuous process improvement, and attentiveness to customer needs allows A.R.E. Manufacturing, Inc. to meet, and ultimately exceed, the customer's expectations.

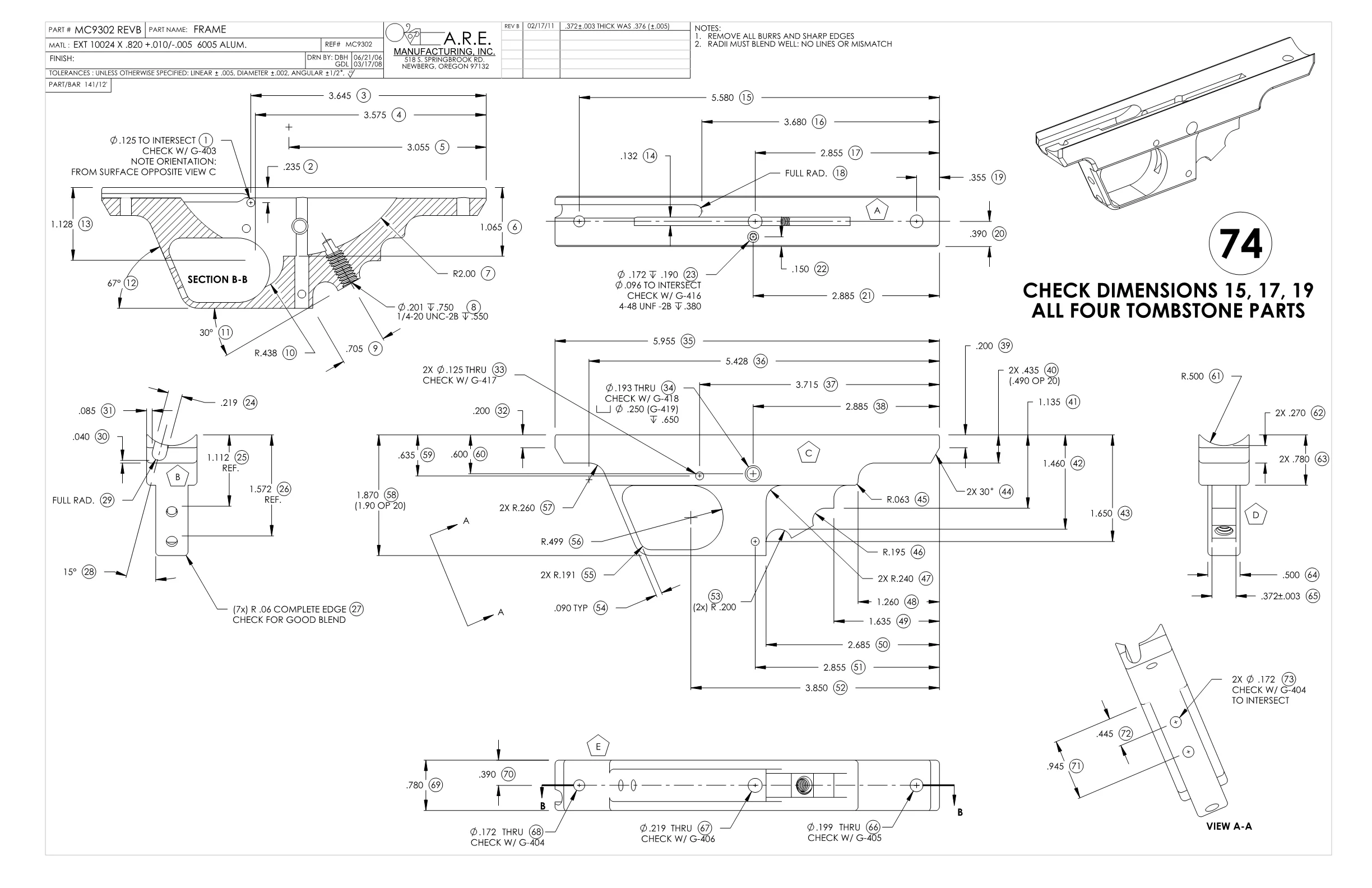

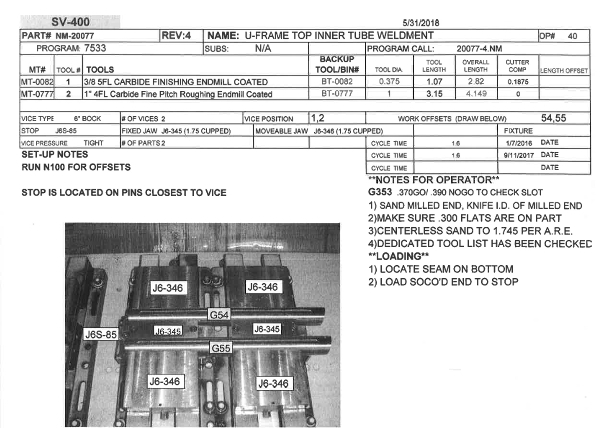

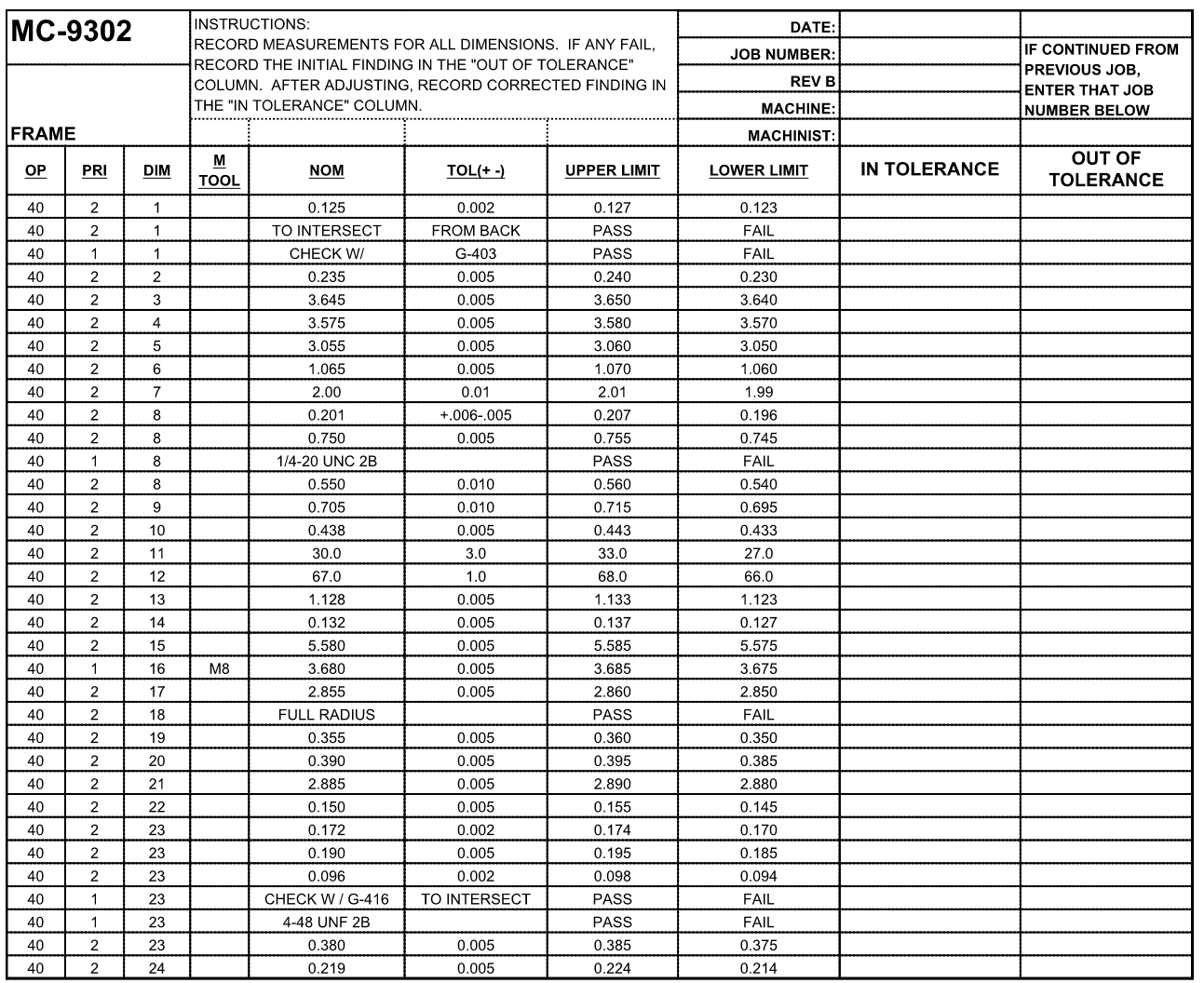

Standard paperwork at A.R.E. Manufacturing includes Blueprint, Set-up Sheet, Production Plan, First Article and Measure Sheet.

Quality inspection

Key to our quality system is standard inspection processes. Your order will be accompanied by a custom Blueprint, Setup Sheet, Production Plan, First Article and Measure Sheet. These ensure that your parts are made to your quality requirements. The Measure Sheet and First Article, in particular will specify what, when and how to measure each dimension during the production run.

CMM inspection is our highest quality, most reliable form of inspection. The repeatability of it can't be beat by human hands. Also, the precision of computerized measuring allows for verification of more complicated measurements, such as GD&T.

CMM Click to see equipment specs.